The Engineering Design Show

9th - 10th October 2024 | Coventry Building Society Arena

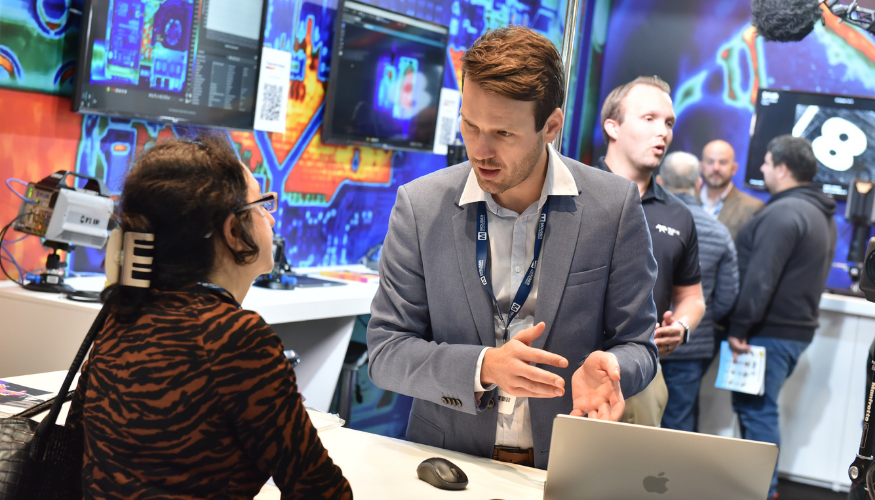

The Engineering Design Show has been showcasing the very best of mechanical, electronics and embedded design for over a decade.

Returning in October, it is THE show for design engineers who are looking for direct access to the latest products, services, and innovations available to the sector. Visitors can explore hundreds of UK and international suppliers and thousands of the latest products and innovations. Alongside the exhibition, there will be a free-to-attend conference and workshops, providing topical content on the challenges, pain points and opportunities for the engineering sector.

Why should you visit EDS?

EDS is the biggest event in the UK for design engineers. Find the solution to your design dilemma at an exhibition of over 200 solution providers, boost your professional development at free-to-attend conference sessions, get expert advice at practical workshops, and discover the latest engineering applications and technologies.

Interested in exhibiting at EDS?

For over a decade, EDS has been delivering engineering buyers, not browsers, and is a must-attend event for anyone wanting to access this difficult-to-reach audience. Exhibiting at EDS is the most effective way of maximising your organisation’s exposure to the UK’s design engineering community.

There's so much to see and do at EDS!

Innovation

There is an exhibitor for your every design need and thousands of innovative products on display across the full mechanical, embedded and electronics design landscape.

Conferences

Curated by The Engineer, Eureka and New Electronics, our programme of speakers never fails to disappoint. Hear from the biggest names in the industry across our two-day programme.

Don't just take our word for it...

-

The resurgent Engineering Design Show exceeded expectations. Ineltek's stand had a steady stream of relevant visitors from a variety of technology businesses. The two days flew by; we never reached the point where we had to kill time visiting other stands. EDS is back with a bang!

-

DS is focused on getting good-quality visitors and we have noticed that people who are visiting EDS are looking for very specific services. We had plenty of good conversations…there was various types of people who were visiting our stand, looking for a variety of things.

-

EDS is a great place to meet all sorts of people who need all sorts of weird and wonderful applications for products. The show has been a great help and very busy. The reason why EDS is so good is that people come to you. Beyond the targeted markets of people we usually try to sell to, we have met people we weren’t really aware of. The show allows you to be found rather than going out and finding the leads yourself.

-

EDS had an excellent atmosphere with each exhibitor stand providing clear and accessible information on products and services. An invaluable event to keep up with technologies in engineering and hear from industry leaders.

-

Engineering Design Show is an exhibition not to be missed. It’s an excellent event for networking and has a strong conference programme.

-

EDS is the simplest way to find everyone in one place. Many companies presented their novelties, and all had something new and exciting to show off.

-

This was the first time Decade Monitoring solutions visited the engineering design show. We would recommend this to our customers to attend in the future. The environment was very friendly, we spoke to many of our clients and there was some amazing digital engineering on display, many solutions for a better future.

Check out the latest EDS news

-

Peli Products (UK) worked in partnership with branding agency, Whiteroom, to deliver a high-performance presentation solution for New Era's exclusive Red Bull Racing baseball caps.

-

Creative Hubb Limited provide a product design, pattern cutting, grading and marker making service for the garment and sewn products industry, the team have a niche specialism in engineered textile pr ...

-

Bluefrog Design and AW Technology Ltd collaborated to broaden AW Technology's product range, resulting in the design and development of The 9200 Series. This innovative equipment is engineered to rigo ...

-

Investing in mould tooling can be significant and the responsibility on the manufacturer to deliver high quality mould tooling solutions within the quoted price is high. Given the nature, and at times ...

-

Chichester, West Sussex, United Kingdom – Nexus Industrial Memory, a leading supplier of industrial-grade memory solutions, today announced their appointment as the official UK, EU, Switzerland and No ...

-

Today, with the focus on businesses to reduce their use of plastic to protect the environment, companies are encouraged to find new innovative ways to package their products. Governing bodies like the ...

-

The medical devices market faces increased pressure to meet rising demand for medical devices, and those intricate devices demand for specialised engineering knowledge and expertise to ensure success ...

-

CREAT3D, leading specialist provider of Additive Manufacturing equipment, solutions and services will be showcasing the latest technology developments in 3D printing for engineering applications at En ...

-

Relec Electronics, a leading distributor of cutting-edge display technology and power conversion products, is gearing up to make a significant impact at the upcoming Electronic Design Show in Coventry ...

-

[Rochester, 02.10.2023] — In response to overwhelming demand from our valued customers, CDS is proud to announce the launch of our comprehensive range of touch monitors that seamlessly integrate with ...

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)